Steel Slag Recycling Plants

Steel slag in China: Treatment, recycling, and management

2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can serve as a substitute for aggregates in civil engineering In this paper, we reviewed 2022年4月6日 Japan and China are two major steel producing countries that have placed a large emphasis on developing new technologies to decrease slag emission or promote slag valorization Slags are almost completely reused or Recycling of ironmaking and steelmaking slags 2019年7月1日 In order to lower the environmental impact of the steel industry and ensure its economic sustainability, there have been significant studies finding the ways to recycle by The recycling and reuse of steelmaking slags — A reviewSteel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can Steel slag in China: Treatment, recycling, and management

An overview of utilization of slag and sludge from steel industries

2007年3月1日 Pilot plant trials successfully demonstrated the viability of recycling million of tons of steel plant dusts and sludge that are now typically land filled, and typically converting them 2024年3月12日 Steel slag recycling primarily involves extracting useful metal components (such as steel particles and iron powder) and properly managing the tailingsSteel Slag Recycling: The Definitive Processing ECOFERTEC is designing customized steel slag processing and metal recovery plants for each projectspecific purposes The newest technology ECOFERTEC slag processing plant enables the most costeffective way to remove steel Steel Slag Processing — EcofertecThe steel industry in North America has been recycling steel scrap for more than 150 years The steel industry needs scrap to produce new steel, which ensures that all steel products contain anywhere from 25 percent up to 100 percent Waste Disposal and Recycling in Steel Industry

The recycling and reuse of steelmaking slags — A review

2019年7月1日 Large volumes of slags are formed as byproducts during the refinement of pig iron by basic oxygen steelmaking or electric arc furnace steelmaking In order to lower the environmental impact of the steel industry and ensure its economic sustainability, there have been significant studies finding the ways to recycle byproductsThe formation, composition and 06/13/2022 JSW Steel’s Vijayanagar Works has inaugurated a slagbased sandmaking plant capable of producing 300,000 metric tons annually, reports The Hindu newspaper in India “The research and development team of JSW Steel Vijayanagar Works has developed this sustainable process for converting steelmaking slag into sand (fine aggregate JSW Steel Starts Slag Recycling Plant AIST2024年6月12日 The highvalue utilization of blast furnace slag (BFS) and steel slag (SS) as a valuable resource in the field of carbon reduction represents a green revolution, and also is an indispensable path toward breaking through resource and environmental constraints and achieving highquality, sustainable development through solid waste utilization in the steel Recycling of iron and steel slag for carbon reduction and low iso 9001, iso 9000, iso 14001, iso 14000, iso 20000, iatf16949, iso 14064Steel slag recycling plant(crushing plant) ATAIRAC

.jpg)

Recycling steel slag from municipal wastewater treatment plants into

2020年1月1日 Recycling steel slag from municipal wastewater treatment plants into concrete applications – A step towards circular economy (Gurung et al, 2013; Hobbie et al, 2017) A fullscale continuous wastewater treatment plant in Waiuku, New Zealand using slag showed 77% phosphate removal over a 5year lifespan of the slag (Shilton et al, 2006 2020年1月1日 Recycling steel slag from municipal wastewater treatment plants into concrete applications – A step towards circular economy A fullscale continuous wastewater treatment plant in Waiuku, New Zealand using slag showed 77% phosphate removal over a 5year lifespan of the slag (Shilton et al, 2006)Recycling steel slag from municipal wastewater treatment plants 2007年3月1日 Integrated steel plants utilize mostly five materials such as raw materials, air, water, fuel and power to produce steel During the production of steel, 2–4 t of wastes are being generated per tonne of steel producedThe various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast furnace flue dust and sludge, An overview of utilization of slag and sludge from steel industriesSemantic Scholar extracted view of "Recycling steel slag from municipal wastewater treatment plants into concrete applications – A step towards circular economy" by R Roychand et al Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo 222,592,849 papers from all fields of science Recycling steel slag from municipal wastewater treatment plants

Recycle Metal From Slag: The Recycling Process JXSC

2021年11月11日 Slag is also called molten slag The melt that floats on the surface of liquid substances such as metals during the pyrometallurgical process is composed mainly of oxides (silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide), and often contains sulfides and a small amount of metal Slag Introduction The composition of the slag is adjusted 2024年10月25日 bottomash generated by Waste to Energy plants A Steel Slag Recycling Recovering metals from steel slags, which is a side product of steel mills Refining the residual to use it for aggregates, cement and concrete production 1 BOF, EAF and LF steel slag A A B Processing line for 700000tpa in Raigarh, India Magsort Slag Process Schematic 4Steel slags zero CO raw material 2 and full recycling Industrial byproduct utilization in concrete has been an important choice of researchers over the years (Khan et al, 2016; Qasrawi, 2014)Steel slag has been utilized as aggregate/cementing material in concrete by various researchers over the years (Faraone et al, 2009)Recycling of metallurgical byproducts will ensure the sustainable industrial production and greener Recent applications of steel slag in construction industryThe mass production of steel is inevitably accompanied by large quantities of slags The treatment of ironmaking and steelmaking slags is a great challenge in the sustainable development of the steel industry Japan and China are two Recycling of ironmaking and steelmaking slags

.jpg)

IRON AND STEEL SLAG USGS Publications Warehouse

2024年1月30日 Recycling: Following removal of entrained metal, slag can be returned to the blast and steel furnaces as ferrous and flux feed, but data on these returns are incomplete Entrained metal, particularly in steel slag, is routinely recovered during slag processing for return to the furnaces and is an important revenue source for slag processors 2020年10月1日 With the rapid development of municipal wastewater treatment plants (WWTPs) in China, the amount of waste activated sludge (WAS) has grown dramatically Steel slag with strong adsorption and chemical precipitation has been used in wastewater treatment recently due to its Recycling WAS and steel slags in making AnGS was a lowcost and Effect of steel slag in recycling waste activated sludge to As a result of growing environmental awareness, steel slag is now highly regarded as a recycled material that can reduce environmental impact due to its resourceconservation and energysaving properties MEKA is designing and manufacturing customized steel slag processing and metal recovery plants for each projectspecific purposesSlag Recycling and Metal Recovery HMA Group2020年2月18日 Table – 1 : Plantwise Capacity of Iron and Steel Slag in the Country Steel Plant Capacity ('000 tpy) Bhilai Steel Plant, Durg, Chhattisgarh 2675 Bokaro Steel Plant, Bokaro, Jharkhand 7884 Rourkela Steel Plant, Rourkela, Odisha 1570 Durgapur Steel Plant, Durgapur, West Bengal 566 IISCO Steel Plant, Burnpur, West Bengal 400 kg/THM*SLAG IRON AND STEEL IBM

.jpg)

Steel Slag Recycling: The Definitive Processing Solution

2024年3月12日 Steel slag is generally obtained in large quantities from steel mills, scrap metal recycling, steel processing plants, and waste processing facilities Steel slag can be classified into the following two types:Steel plant slag is a solid industrial waste generated from steel industries in production of steel and mainly these wastes includes blast furnace and steel melting slag (open hearth or LD process slag) (Kourounis et al, 2007; Goldring et al, 1997) The reuse and recycle of the steel slag is closely related to its chemical and physical An Overview of Use of LinzDonawitz (LD) Steel Slag in Agriculture2022年4月6日 ample, hot stage processing of slags for materials as well as heat recovery techniques has been widely applied in steel plants with good results However, increasing the utilization ratio of basic oxygen furnace slags remains a major challenge Technological innovations in slag recycling are crucial for the steel industries in Japan and ChinaRecycling of ironmaking and steelmaking slags in Japan We have continued to promote efforts to recycle iron and steel slag *, dust and other byproducts generated at our works as a result of the steelmaking process In fiscal 2011, our recycling rate came to 963% for all Kobe Steel plants, and 959% for the entire GroupPromoting Recycling KOBE STEEL, LTD

.jpg)

Steel slag in China: Treatment, recycling, and management

2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can serve as a 2024年2月15日 The problem of steel slag could be solved by expanding the utilization ways of steel slag At present, steel slag has been used in the production of cement, the construction of urban roads and the production of fertilizer (Fronek et al, 2012; Jiang et al, 2018b; Shi and Qian, 2000; Wang and Cai, 2006)In developed countries, the utilization rate of steel slag is close to Vanadium extraction from steel slag: Generation, recycling 2019年10月21日 Request PDF Recycling steel slag from municipal wastewater treatment plants into concrete applications – A step towards circular economy Municipal wastewater is a major source of the release Recycling steel slag from municipal wastewater Kobe Steel promotes the recycling of slag and dust generated as a byproduct of ironmaking Beginning in fiscal 1992, Kobe Steel developed an action program targeting waste and has been promoting waste reduction and recycling on an ongoing basis In fiscal 2009, the recycling rate was 928% for all Kobe Steel plants and 927% for the entire GroupResource Recycling Measures KOBE STEEL, LTD

(PDF) An overview on Steel Plant Waste Management in India

2014年6月21日 The steel plant slag mainly includes blast furnace slag and steel melting slag (LD process slag) Solid waste recycling through sinter status at Tata Steel Proc of Environment and Waste 2020年4月21日 With the increase in iron/steel production, the higher volume of byproducts (slag) generated necessitates its efficient recycling Because the LinzDonawitz (LD) slag is rich in silicon (Si) and Steel slag amendment impacts on soil microbial communities 2024年11月1日 The green, efficient, and pollutionfree recycling of metallurgical waste slag has garnered global attention This study reviews the latest technologies for the recycling of steel slag (SS) and ladle refining slag (LFS), as well as the recent advancements in impurity element recovery using an applied electric fieldRecent research progress on recycling metallurgical waste slag 2023年11月20日 Looking at the merits and associated benefits, some of the top steelproducing countries have adopted or upgraded with a recycling technique of steel slags from time to time for various applications (as shown in Fig 3), such as for road construction, soil enrichment, cement production, etc Notably, recycling steel slag for a particular application is associated with A Review on Environmental Concerns and Technological

.jpg)

(PDF) Recycling of ladle slag in the EAF: A way to improve

2007年2月1日 slag recycling in all European steel plants will possibly reduce by about 30 percent the utilization of natural limestones, an ideal perspective environmentally, considering the2018年8月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can serve as a substitute for aggregates in civil engineering In this paper, we reviewed steel slag treatment, recycling, and management in ChinaSteel slag in China: Treatment, recycling, and management2019年7月1日 Large volumes of slags are formed as byproducts during the refinement of pig iron by basic oxygen steelmaking or electric arc furnace steelmaking In order to lower the environmental impact of the steel industry and ensure its economic sustainability, there have been significant studies finding the ways to recycle byproductsThe formation, composition and The recycling and reuse of steelmaking slags — A review06/13/2022 JSW Steel’s Vijayanagar Works has inaugurated a slagbased sandmaking plant capable of producing 300,000 metric tons annually, reports The Hindu newspaper in India “The research and development team of JSW Steel Vijayanagar Works has developed this sustainable process for converting steelmaking slag into sand (fine aggregate JSW Steel Starts Slag Recycling Plant AIST

.jpg)

Recycling of iron and steel slag for carbon reduction and low

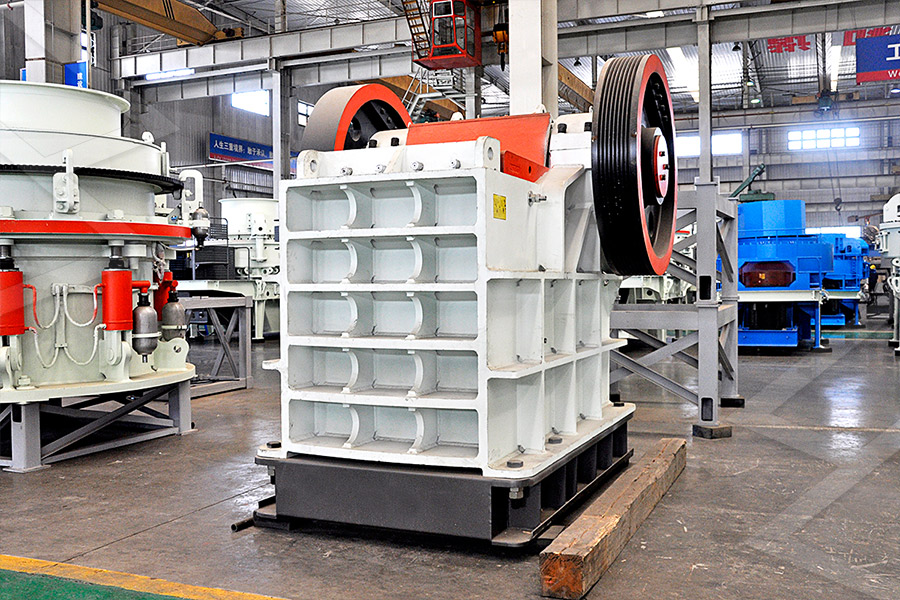

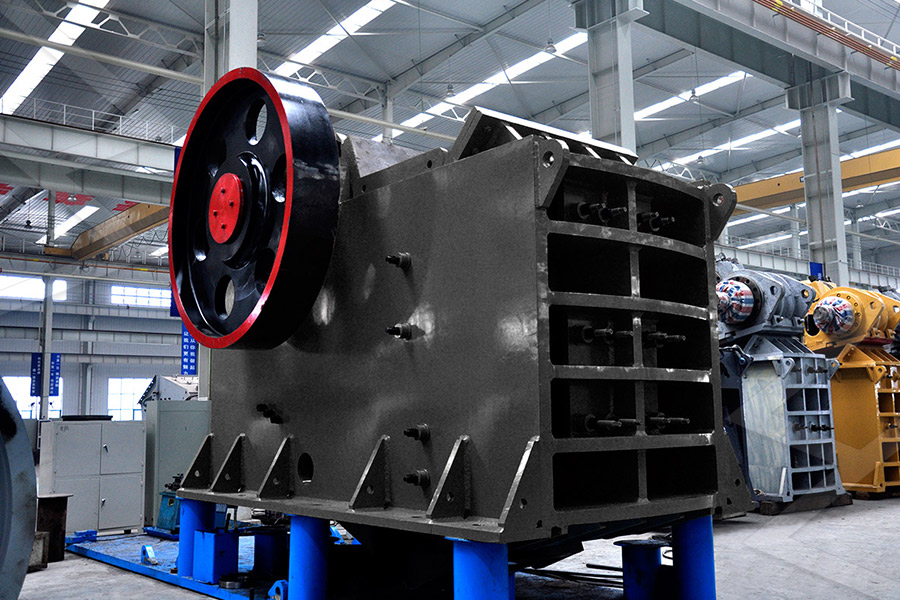

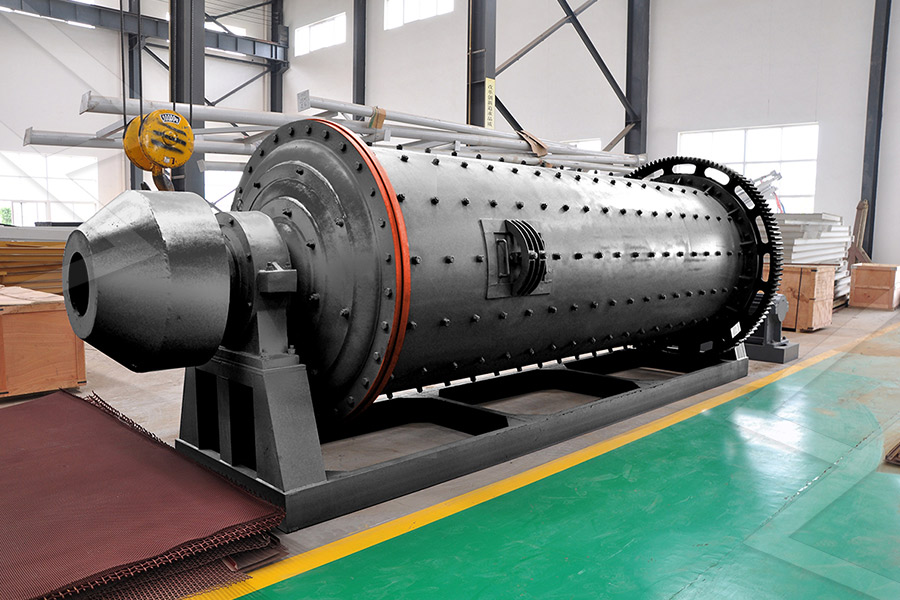

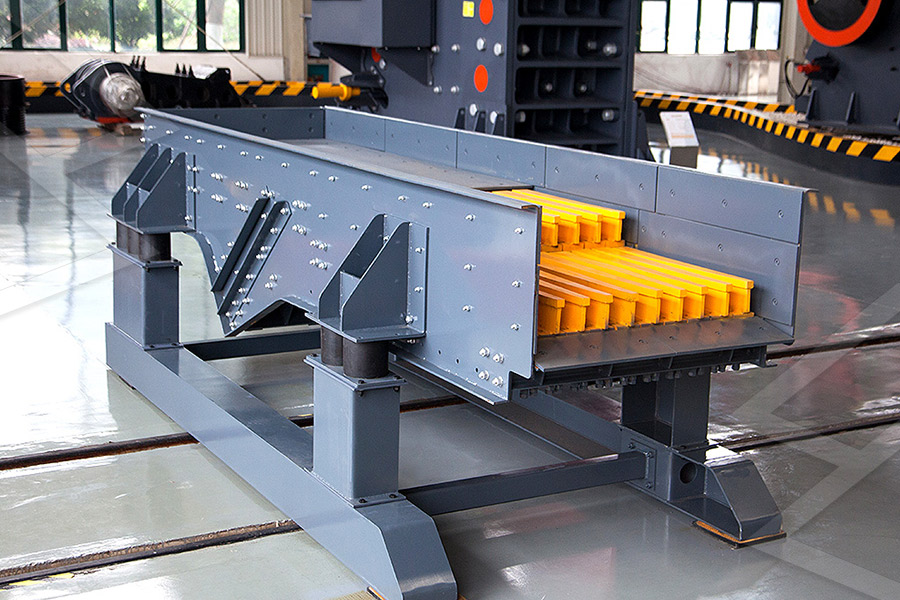

2024年6月12日 The highvalue utilization of blast furnace slag (BFS) and steel slag (SS) as a valuable resource in the field of carbon reduction represents a green revolution, and also is an indispensable path toward breaking through resource and environmental constraints and achieving highquality, sustainable development through solid waste utilization in the steel iso 9001, iso 9000, iso 14001, iso 14000, iso 20000, iatf16949, iso 14064Steel slag recycling plant(crushing plant) ATAIRAC 2020年1月1日 Recycling steel slag from municipal wastewater treatment plants into concrete applications – A step towards circular economy (Gurung et al, 2013; Hobbie et al, 2017) A fullscale continuous wastewater treatment plant in Waiuku, New Zealand using slag showed 77% phosphate removal over a 5year lifespan of the slag (Shilton et al, 2006 Recycling steel slag from municipal wastewater treatment plants into 2020年1月1日 Recycling steel slag from municipal wastewater treatment plants into concrete applications – A step towards circular economy A fullscale continuous wastewater treatment plant in Waiuku, New Zealand using slag showed 77% phosphate removal over a 5year lifespan of the slag (Shilton et al, 2006)Recycling steel slag from municipal wastewater treatment plants

An overview of utilization of slag and sludge from steel industries

2007年3月1日 Integrated steel plants utilize mostly five materials such as raw materials, air, water, fuel and power to produce steel During the production of steel, 2–4 t of wastes are being generated per tonne of steel producedThe various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast furnace flue dust and sludge, Semantic Scholar extracted view of "Recycling steel slag from municipal wastewater treatment plants into concrete applications – A step towards circular economy" by R Roychand et al Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo 222,592,849 papers from all fields of science Recycling steel slag from municipal wastewater treatment plants 2021年11月11日 Slag is also called molten slag The melt that floats on the surface of liquid substances such as metals during the pyrometallurgical process is composed mainly of oxides (silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide), and often contains sulfides and a small amount of metal Slag Introduction The composition of the slag is adjusted Recycle Metal From Slag: The Recycling Process JXSC 2024年10月25日 bottomash generated by Waste to Energy plants A Steel Slag Recycling Recovering metals from steel slags, which is a side product of steel mills Refining the residual to use it for aggregates, cement and concrete production 1 BOF, EAF and LF steel slag A A B Processing line for 700000tpa in Raigarh, India Magsort Slag Process Schematic 4Steel slags zero CO raw material 2 and full recycling