Energy Saving Industrial Ball Mill

.jpg)

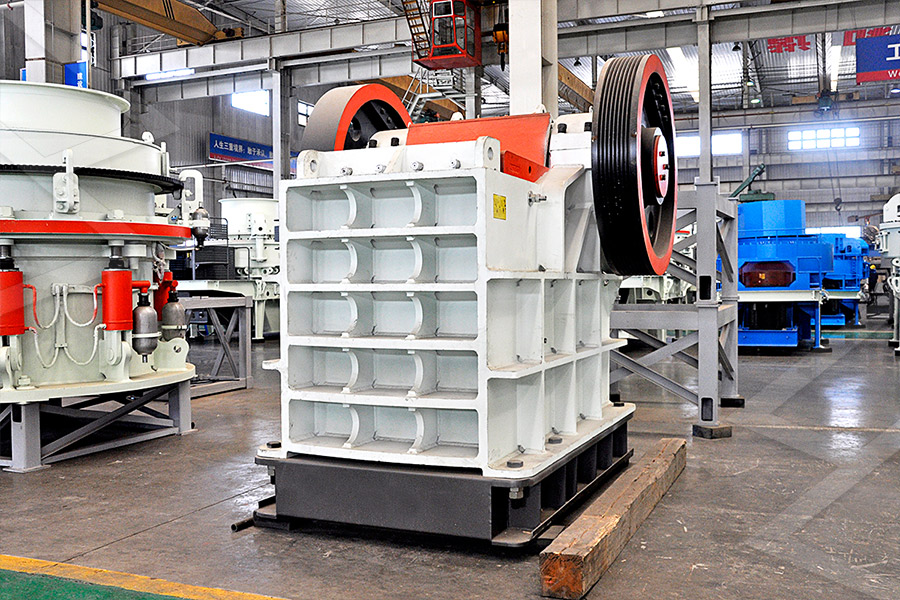

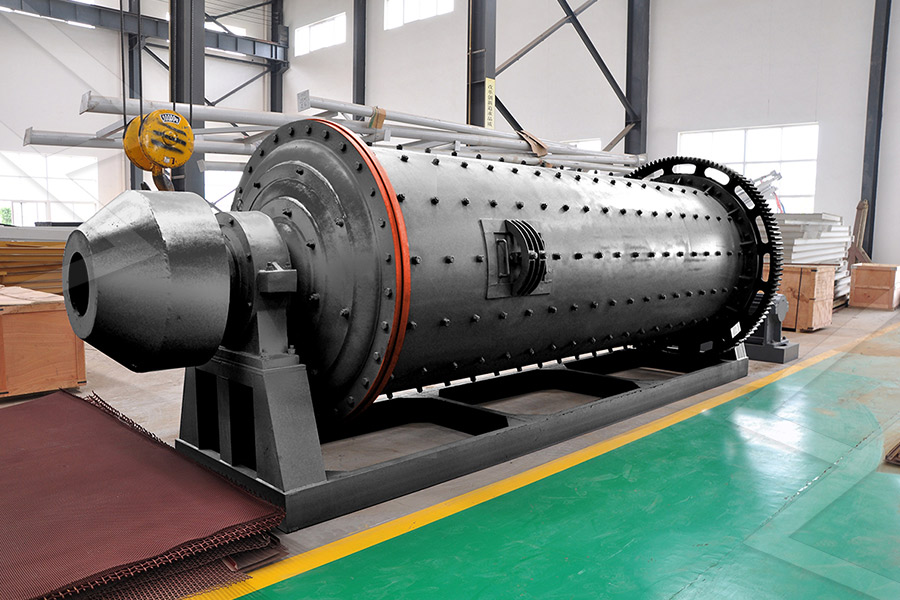

Energy Efficiency Solutions Ball Mill WEG

Ball Mills are widely used in the ceramic and mining industries, where the grinding process requires strict grain size control WEG developed an efficient solution for this application, Energysaving ball mill is a new type of ball mill grinder developed based on the ordinary ball mill It can reduce energy consumption by 30% and increase the capacity by 1520% AGICO offers highefficiency energy saving ball millsENERGY SAVING BALL MILL2024年11月1日 Examined the impact of media density on collision energy characteristics and liner wear This study investigates why ceramic balls achieve superior grinding performance Understanding the EnergySaving mechanism of ceramic balls 2024年11月1日 Examined the impact of media density on collision energy characteristics and liner wear This study investigates why ceramic balls achieve superior grinding performance Understanding the EnergySaving mechanism of ceramic balls

.jpg)

ENERGY SAVINGS AND TECHNOLOGY COMPARISON

2018年2月20日 In ball mills, energy savings vary from 10 per cent to 40 per cent compared to 25 mm media A regrind ball mill with a mix of small grinding media can be as energy effi cient as Numerous design innovations have been done on ball mills but these inefficiencies still persist, hence the need to further design an energyefficient ball mill for industrial use This review Ball Mill Energy Efficiency Optimization Techniques: A ReviewThe energysaving industrial ball mill addresses these concerns by reducing energy consumption by up to 30% compared to traditional ball mills This substantial energy savings translates to China EnergySaving Industrial Ball Mill – stone cruxder2024年8月23日 Compared with traditional ball mills, energysaving ball mill reduces energy consumption and improve grinding efficiency by optimizing design and using a more efficient Energysaving Ball Mill VS Cement Ball Mill JXSC Mineral

Understanding the EnergySaving mechanism of ceramic balls

2024年11月1日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency2024年1月31日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particles This paper introduces a Enhancing the Grinding Efficiency of a Magnetite 2013年7月15日 The energy saving resulting from the replacement of cyclones with screens in a closed ball mill circuit was estimated to be in the range of 10 to 25% (Jankovic and Valery, 2012a) An analysis of theEnergy Efficient Ball Mill Circuit – Equipment 2016年2月1日 A specific energybased size reduction model for batch grinding ball mills has been developed (Shi and Xie, 2015) The objective of this work was to overcome the limitations in the existing JKMRC (Julius Kruttschnitt Mineral Research Centre) perfect mixing ball mill model, including the use of a set of default breakage appearance functions for all ores, and the A specific energybased ball mill model: From batch grinding

.jpg)

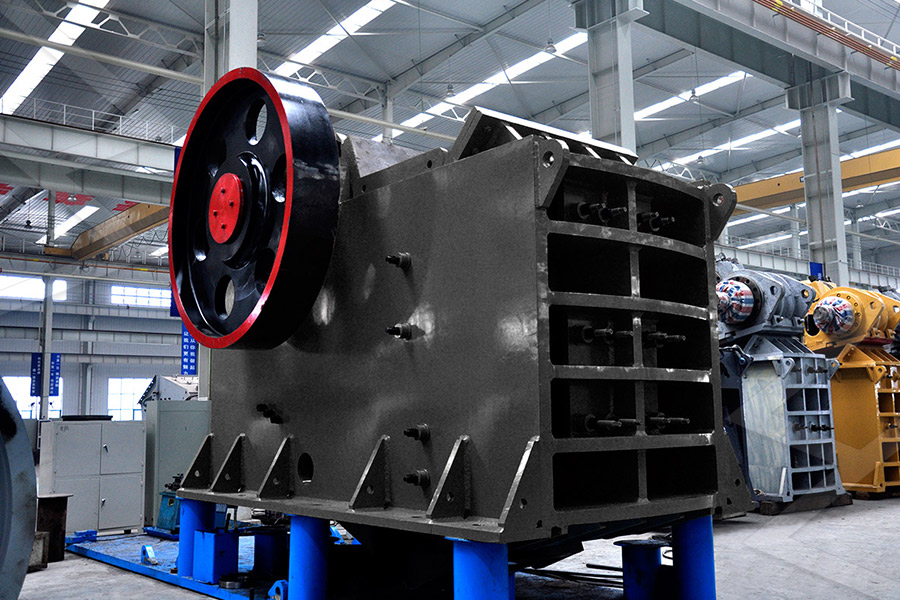

Energy Efficiency Analysis of Copper Ore Ball Mill Drive

2021年2月26日 Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high rotational masses The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading One method for increasing the energy efficiency of ball mills is to optimize their drive systems This article 2022年11月1日 Recent research contends that ceramic balls significantly reduce energy consumption in industrial tumbling mills In this work, the binary media method is proposed to enhance ceramic ball grinding performance Specifically, when feed ore hardness is high and the ceramic ball grinding effect on coarse minerals degrades, a certain proportion of steel balls Can ceramic balls and steel balls be combined in an industrial 2016年10月5日 Comparisons between different energyefficient grinding technologies and applications were presented for production of cement with energy savings Industrialscale data related to Horomill® and Polysius® HPGR/twocompartment ball mill circuit provided insights into the operational and sizereduction characteristics of Horomill® and HPGR/two EnergyEfficient Technologies in Cement Grinding2017年1月17日 The grinding process in ball mills is notoriously known to be highly inefficient: only 1 to 2% of the inputted electrical energy serves for creating new surfacesBreaking down energy consumption in industrial grinding mills

The working principle and seven advantages of energysaving ball mill

2024年10月24日 In today's mineral processing plants, energysaving ball mills for mineral processing can often be seenWhether it is a metal ore or a nonmetallic ore, as long as the useful mineral is in a finegrained embedded state, it must be ground into a finer particle size in order to separate the useful mineral from the gangue mineral Crushing equipment alone cannot meet The energysaving industrial ball mill addresses these concerns by reducing energy consumption by up to 30% compared to traditional ball mills This substantial energy savings translates to lower carbon emissions and a more sustainable mining process China EnergySaving Industrial Ball Mill – stone cruxder2023年11月21日 vides a reference for the subsequent research on energy saving and consumption reduction in ball milling op erations The optimal grinding parameters were determined to be grinding concentration Energy conservation and consumption reduction in 2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) (PDF) Grinding in Ball Mills: Modeling and Process Control

Attritor Ball Mill Superfine Grinding Stirred Ball

Attritor ball mill also called stirred ball mill, is a kind of ultrafine grinding equipment with high output and energy saving With the development of science and technology, there are more and more applications of ultrafine powders in AGICO offers quality industrial ball mills Feel free to contact us! Skip to content [gtranslate] info@ballmillmachines +86 Home; Ball Mill Application Menu Toggle Cement Ball Mill; Gold Ball Mill; Coal Ball Mill Batch Ball Mill – Batch Type Ball Mill For SaleLower Energy Consumption: By minimizing frictional losses and optimizing grinding processes, energysaving ball mills significantly reduce energy consumption compared to conventional mills 2The Role of EnergySaving Ball Mills in Mineral Processing2021年3月23日 New ball mill drive system with the prototype energysaving SMH motor [37] Startup of the LSPMSM SMH1732T motor with a filled ball mill after two hours of downtime: (a) active power, (b Energy Efficiency Analysis of Copper Ore Ball Mill Drive

EnergySaving Ball Mill Henan Light Industrial Products

Description of Energysaving ball mill: The ball mill is used to grind many kinds of mine and other materials, or to select the mi Ships from China Korean Suppliers Henan Light Industrial Products Import And Export Co, Ltd Free member Since 2011 Henan, China 2015年7月3日 An energysaving ball mill is an efficient tool for grinding many materials into fine powder after they have been broken into certain sizes It is widely used in the chemical industry, new building materials, silicate products, fireproof materials, fertilizer industry, black and nonferrous metal processing, as well as glassceramics industry, It does dry or wet grinding for all Energysaving Ball Mill Introduction Skew Rolling Mill2024年11月1日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particlesUnderstanding the EnergySaving mechanism of ceramic balls 2020年2月26日 Owing to the lack of effective energy consumption models of ball mills in the ceramic industry, a calculation model to forecast energy consumption of ceramic ball mills during the grinding process Calculation method and its application for energy consumption of ball

.jpg)

Energy conservation and consumption reduction in grinding

2023年11月1日 The research and development of stirring mills abroad began in the 1940s, and the technology of stirring mills developed rapidly in the 1960s, while the development of domestic stirring mills started in the early 1970sAfter years of development, stirring mills were developed into a wide variety of grinding equipment with various types and models, which were gradually 2022年8月29日 In industrial conditions, mill speed can be regulated, for example, with the use of systems based on programmable logic controllers (PLCs) [21] In the future, an important Energy savings may also be found in the ball mill drive systems In the scale of a processing plant, the electric motors of these drive systems account for 95% of the Energy Efficiency Analysis of Copper Ore Ball Mill Drive 2024年6月5日 By adjusting the gradation of the steel balls, the size and amount of the discharge fineness can be changed The highefficiency and energysaving ball mills produced by our company are all supported by rolling bearings Energy Saving Ball Mill Hongji Mine MachineryWhat is Energy Saving Factory Price Ball Mill Mining Industrial Ball Mill, ball mill manufacturers suppliers on Video Channel of MadeinChina Home Video Channel What is Energy Saving Factory Price Ball Mill Mining Industrial Ball Mill Ball Mill US$6,4500015,00000 / Set View What is Energy Saving Factory Price Ball Mill Mining Industrial Ball Mill

Energy Saving Ball Mill JXSC minejxsc

Energy Saving Ball Mill Home Energy Saving Ball Mill As a trusted ball mill manufacturer with 37 years of experience, JXSC has been delivering excellence since 1985 We’ve completed over 200 mining projects in 40+ countries, offering comprehensive services including RD, production, installation, and free operational training Our ball mills, which use steel balls for []The energysaving ball mill reduces power consumption while maintaining high efficiency, ideal for costeffective grinding in mining and industrial applications Grate Ball Mill The grate ball mill allows efficient discharge of materials, reducing overgrinding, making it ideal for coarse materials in mining and mineral processingBall Mills Manufacturer JXSC2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study per‐ formed on a EnergyEfficient Technologies in Cement GrindingThe mini ball mill is a type of smallscale ball mill grinder Compared with the industrial large ball mill, it is suitable for trial production and small batch production At present, there are many kinds of small ball mills in the market The common ones Mini Ball Mill – Mineral Grinding Small Ball Mill For Sale

.jpg)

(PDF) Performance optimization of an industrial ball mill for

2017年1月1日 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single stage SAG mill These scats are non spherical ball fragments resulting from uneven wear of balls Ball mills are essential machinery in the mining industry, thermal powerproducing companies, and cement manufacturing companies, for grinding different ores, grinding coal into pulverized coal, and processing cement clinkers into fine powder cement or pulp Their design operational and energy inefficiencies are because of drivetrain inefficiencies, output load rerun, lifter face Ball Mill Energy Efficiency Optimization Techniques: A Review2020年5月1日 The results demonstrated that closedcircuit enhanced the overall efficiency of the twocompartment cement ball mill at the same final product fineness by decreasing the electrical energy Genec [26] modeled an open circuit CBM with three compartments which was an industrial scale FLSmidth ball mill It was understood from the simulation Energy and exergy analyses for a cement ball mill of a new 2024年1月31日 Ceramic ball milling has demonstrated remarkable energysaving efficiency in industrial applications However, there is a pressing need to enhance the grinding efficiency for coarse particles This paper introduces a Enhancing the Grinding Efficiency of a Magnetite

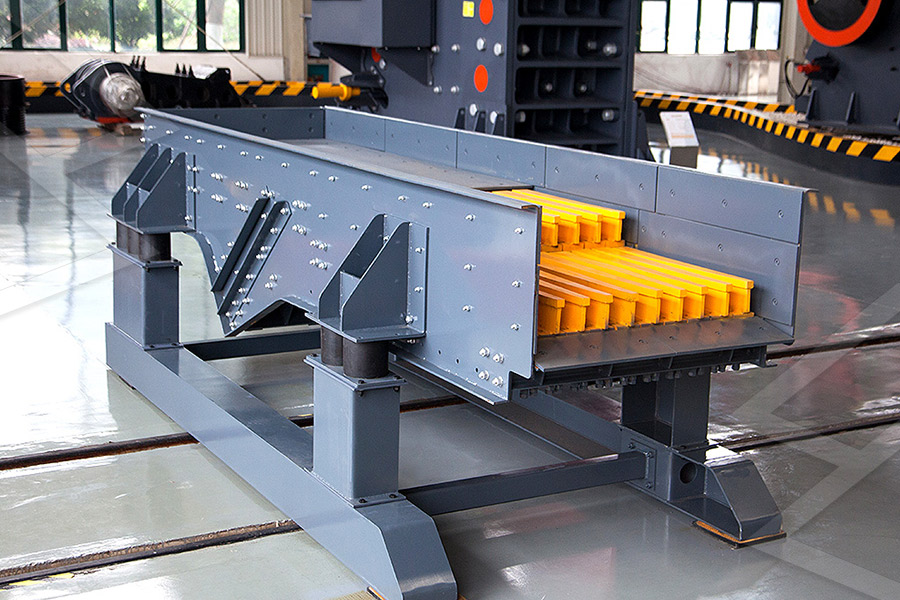

Energy Efficient Ball Mill Circuit – Equipment

2013年7月15日 The energy saving resulting from the replacement of cyclones with screens in a closed ball mill circuit was estimated to be in the range of 10 to 25% (Jankovic and Valery, 2012a) An analysis of the2016年2月1日 A specific energybased size reduction model for batch grinding ball mills has been developed (Shi and Xie, 2015) The objective of this work was to overcome the limitations in the existing JKMRC (Julius Kruttschnitt Mineral Research Centre) perfect mixing ball mill model, including the use of a set of default breakage appearance functions for all ores, and the A specific energybased ball mill model: From batch grinding 2021年2月26日 Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high rotational masses The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading One method for increasing the energy efficiency of ball mills is to optimize their drive systems This article Energy Efficiency Analysis of Copper Ore Ball Mill Drive 2022年11月1日 Recent research contends that ceramic balls significantly reduce energy consumption in industrial tumbling mills In this work, the binary media method is proposed to enhance ceramic ball grinding performance Specifically, when feed ore hardness is high and the ceramic ball grinding effect on coarse minerals degrades, a certain proportion of steel balls Can ceramic balls and steel balls be combined in an industrial

EnergyEfficient Technologies in Cement Grinding

2016年10月5日 Comparisons between different energyefficient grinding technologies and applications were presented for production of cement with energy savings Industrialscale data related to Horomill® and Polysius® HPGR/twocompartment ball mill circuit provided insights into the operational and sizereduction characteristics of Horomill® and HPGR/two 2017年1月17日 The grinding process in ball mills is notoriously known to be highly inefficient: only 1 to 2% of the inputted electrical energy serves for creating new surfacesBreaking down energy consumption in industrial grinding mills2024年10月24日 In today's mineral processing plants, energysaving ball mills for mineral processing can often be seenWhether it is a metal ore or a nonmetallic ore, as long as the useful mineral is in a finegrained embedded state, it must be ground into a finer particle size in order to separate the useful mineral from the gangue mineral Crushing equipment alone cannot meet The working principle and seven advantages of energysaving ball mill The energysaving industrial ball mill addresses these concerns by reducing energy consumption by up to 30% compared to traditional ball mills This substantial energy savings translates to lower carbon emissions and a more sustainable mining process China EnergySaving Industrial Ball Mill – stone cruxder

.jpg)

Energy conservation and consumption reduction in

2023年11月21日 vides a reference for the subsequent research on energy saving and consumption reduction in ball milling op erations The optimal grinding parameters were determined to be grinding concentration