Aggregate Flow Diagram And Typical Crushing And Screening Plant Layout

.jpg)

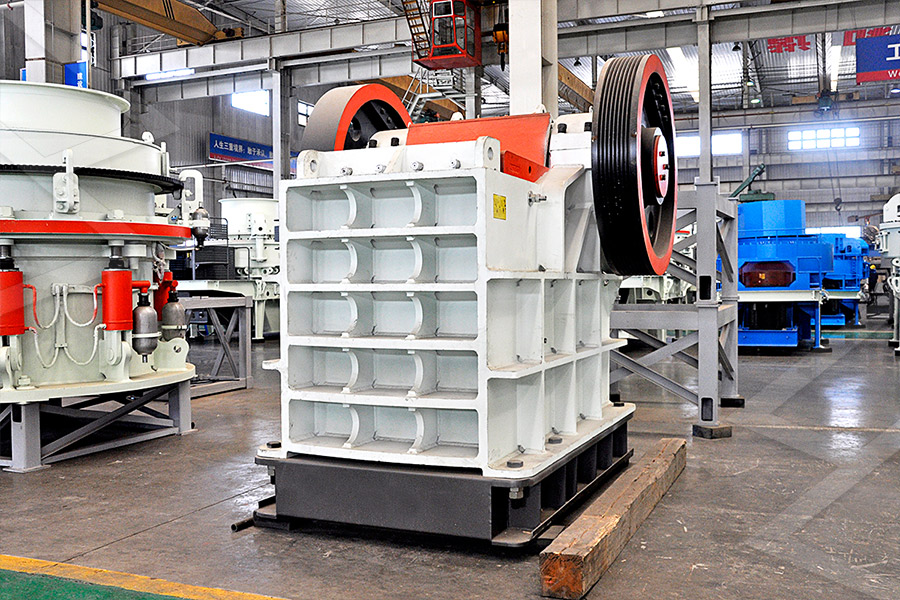

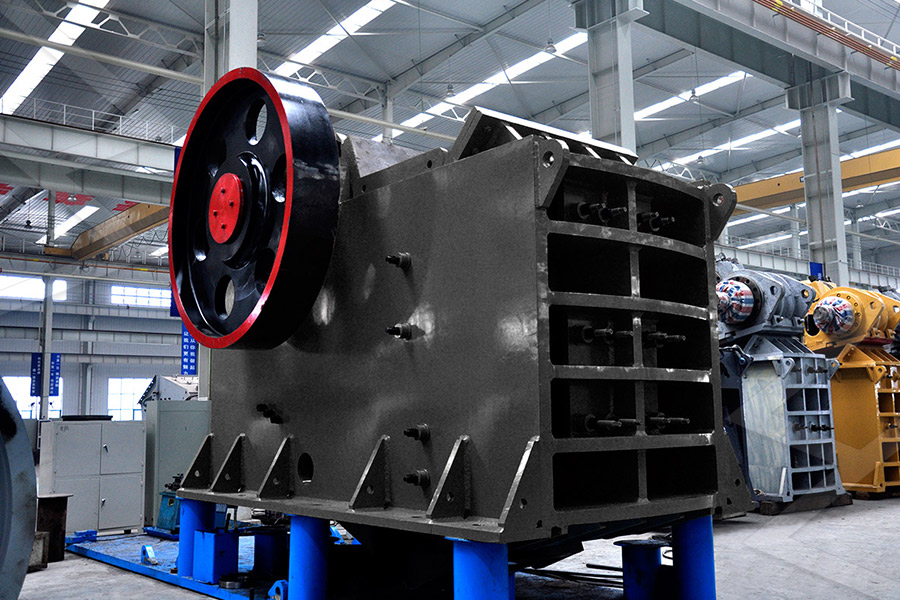

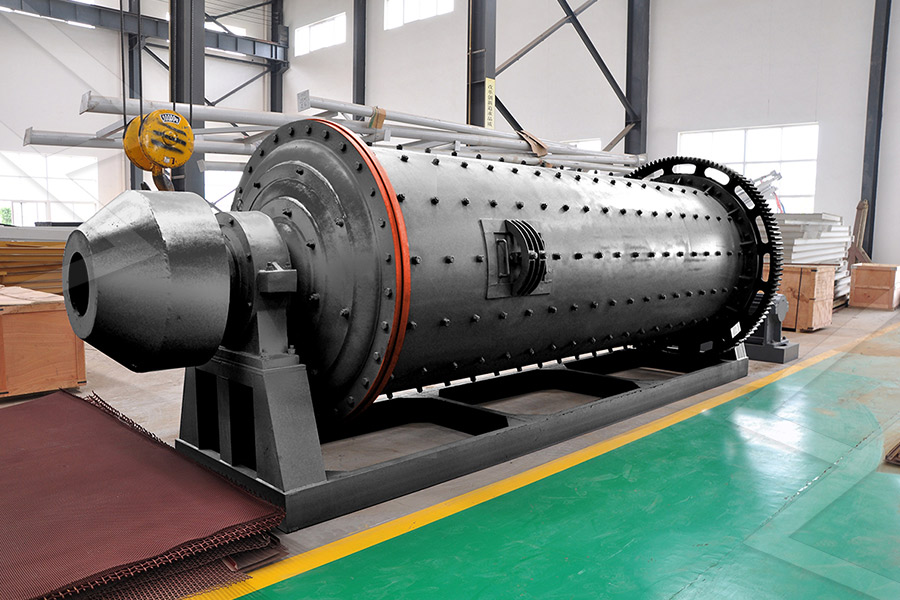

Crushing Plant Design and Layout Considerations 911

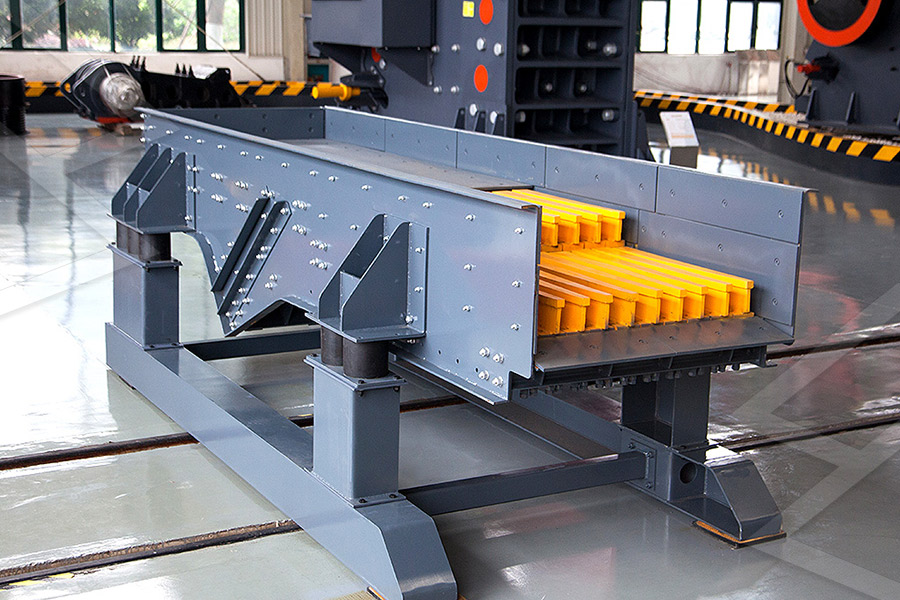

2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and A flow diagram for an aggregate processing plant is shown here This flow diagram Crushing Screening Plan2016年4月14日 A flow diagram for an aggregate processing plant is shown here This flow diagram shows a threestage gravel plant schematically It shows the interrelationships and functions of the various components of the plant Crushing Screening Plant Design FactorsThe plant must be set up on firm level ground and as near as possible to the source of material to be and positioned so the conveyors may expel the processed aggregate to the desired location for stock piling or hauling Figure 4 Aggregate Crushing and Screening Plant

.jpg)

Schematic description of the crushing plant, (1)

A fundamental understanding of the factors influencing particle shape is of central importance for optimisation of the output quality from crushing plants for aggregate productionIntegrated Publishing, Inc A (SDVOSB) Service Disabled Veteran Owned Small BusinessFigure 3 Aggregate flow diagram and typical The results show the process of generating knowledge for alternative crushing plant operation settings and how the choices can be selected and eliminated using boundary conditionsLayout of a fourstage crushing plant for ballast productionA typical flow diagram of a crushingscreening plant to produce concrete aggregates in Turkey In this study, the capacity (Q) of Apron feeders is investigated throughA typical flow diagram of a crushingscreening plant to

(PDF) Crushing and Screening Handbook

Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance This paper assesses a number of factors affecting the performance of the crushing plant Yeco Machinery’s engineers will prepare a layout that suits the design criteria, flowsheet and selected equipment in the most economical possible configuration It’s important to keep structural costs down, to design for ease of maintenance Crushing Plant Design and Layout Yeco Download scientific diagram Layout of a fourstage crushing plant for ballast production from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the aggregate Layout of a fourstage crushing plant for ballast productionSince the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance This paper assesses a number of factors affecting the performance of the crushing plant (PDF) Crushing and Screening Handbook

.jpg)

My Plant Planner Metso

My Plant Planner is a freetouse drag and drop plant simulator and configurator that helps you design more productive and efficient plants through realtime insights Design and simulate a new crushing and screening plant in 3D or 2024年7月26日 The life of the mine is a key element in the design of any crushing plant Shortterm mine lives (three to eight years) require a very careful approach to design, layout and construction Since the crushing plant’s structure and enclosure can represent the largest single cost element in a primary crushing plant, it is imperative to optimize Crushing Plant Design and Layout Considerations 911 2013年3月24日 Aggregate flow diagram and typical crushing and screening plant layout Back Up Next: Click Aggregate crushing process plant design,flow charts,layout If you are looking for Aggregate crushing process plant you got to the right place! kefid China's capabilities in mineral testing process design, project management aggregate plant layout Mining Quarry Plant miningcrushing2012年10月15日 Several considerations need to be taken into account in designing an efficient crushing and screening plant, the first being the raw materials to be crushed The entire system should be checked by an experienced crushing and screening expert with a computer flow simulation program to optimize the output and efficiency Hopper designCrushing and Screening AggNet

Crushing and Screening Handbook Metso

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process Explore Mining Explore commodities Crushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates 2023年2月23日 Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability in the aggregates industryThe Ultimate Guide to Designing an Efficient Aggregate Crushing Plantcrushing and screening layout hoftweewielers We have Aggregates Screening And Crushing Layout,Crushing plant design and layout considerationscrushing circuit a shows a small simple layout for use in mills up to 100 tons in order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day crushing and screening plant layout jakkalsvalleicoWrite better code with AI Security Find and fix vulnerabilitiessbm/sbm aggregate flow diagram and typical crushing and screening

aggregate flow diagram and typical crushing and screening plant layout

the maximum capacity can be 1000t/h if want a higher Get Price schematic flow diagram of aggregate crushing plant 2021 5 31 schematic diagram for screening plants iappleboy Aggregate Crushing And Screening Plant Layout 28 Views The kefid is the professional mining equipments manufacturer in the world, located in China,India, along with crushing and screening plant layouts Mining Quarry PlantThis method simulated the complete crushing process of the cone crusher and realized loop optimization Moreover, researchers have proposed the empirical model (Eloranta and Evertsson, 2006), the Schematic description of the crushing plant, (1) In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum A welldesigned plant layout balances the capital versus operating cost over mine lifeCrushing Plant Design and Layout Yeco Machinery

.jpg)

Optimization and Simulation of Operation Performance in Crushing Plants

2019年10月25日 This research includes optimization of aggregate production of the stone crushing plant using fuzzy modelling The investigation includes onsite aggregate testing and fuzzy logic implementation Fuzzy modelling is a type of computerized reasoning used to simulate the real plant operation In this work, a lot of agent degree information for crushers were Stone crushing plant Flow chart: SBM 250TPH 300 TPH stone crushing screening plant is our small and medium scale crusher plant It is mainly consist of ZSW490×130 Vibrating Feeder, PE900×1200 Jaw crusher, PF1315 Impact crusher, and 3YA2160 Vibrating screen SBM can design the stone crushing plant flow chart according to the raw materialsStone crushing screening plant of 250 TPH unisbmDownload scientific diagram A typical flow diagram of a crushingscreening plant to produce concrete aggregates in Turkey from publication: EVALUATION OF THE CAPACITY OF APRON FEEDERS USED IN A typical flow diagram of a crushingscreening plant to Integrated Publishing, Inc A (SDVOSB) Service Disabled Veteran Owned Small BusinessFigure 3 Aggregate flow diagram and typical crushing and screening

.jpg)

Figure 3 Aggregate flow diagram and typical crushing and screening

Integrated Publishing, Inc A (SDVOSB) Service Disabled Veteran Owned Small Business2022年6月27日 point to do that is at screening For that critical step you can trust MEKA Horizontal Screens The screens elliptical motion is combined with high acceleration, thereby bringing more power into play than in traditional screens This ‘’high power’’ feature delivers better performance in terms of both throughput and screening efficiencyMEKA CRUSHING SCREENING AND CONCRETE 2021年12月3日 The flow chart of the crushing – screening plant is given in Fig 2 In typical crushing – screening operations, rock b locks are initially scalped using a 70 mm grizzly feeder before first (PDF) INVESTIGATION OF ROCK AGGREGATE illustrates a typical crushing and screening plant layout where the crusher maybe utilized as a component The positions of the various components may be changed as required For example, only the final discharge Aggregate flow diagram and typical crushing and screening plant layout TA 4 TM 53820205101TM 53820205101 Liberated Manuals

Phoenix Mining Equipment (Shanghai) Co, Ltd

Manufacturer of Complete Crushing Screening Plants Phoenix is committing to inspire the traditional mining industry with emerging technology and create a smart, environmentallyfriendly and energy saving crushing and screening system in line with the development of the new era Free consulting service of flow chart design for crushing Crushing Plant Process Optimisation Design of processes in order to find the most efficient solution to a specific task is a difficult problem Often the number of solutions are large and the optimal solution is therefore difficult to identifyx000D Crushing plant process design is no exception from this statement In order to find the best solution issues like equipment selection Crushing Plant Process Optimisation AusIMMtypical gabro crushing screening plant layout; Typical flow sheet of a coal processing plant A Typical Flow Chart for Coal Beneficiation 11 of a Coal Washery In mining operations, the layout of crushing plants and ancillary equipment and flow diagram of a typical aggregate schematic plant layout diagram for primary mobile typical gabro crushing screening plant layout alterbatiGeneral flow chart belonging to the Bornova 2023年3月7日 Download scientific diagram General flow chart belonging to the Bornova stone aggregate crushing facil INICIO; PRODUCTOS; NOTICIAS; SOBRE NOSOTROS; CONTÁCTENOS; Whatsapp 24h Online flow chart for aggregate crushing plant T02:01:25+00:00 Planta de Trituradora flow chart for aggregate crushing plant

aggregate flow diagram and typical crushing and screening

Aggregate flow diagram and typical crushing and TM 53820205101 Figure 3 Aggregate flow diagram and typical crushing and screening plant layout Aggregate flow diagram and typical crushing and screening plant layout BackUpNext Information Categories Related Information syntron vibratory feeder mf 1000; burma stone aggregate 2015年1月1日 This paper deepens the work published earlier by Airikka (2015) 2 CRUSHING AND SCREENING PROCESS A crushing and screening plant, that is, an aggregate production process, starts with humanbased material feeding ending to aggregate fraction piles each of them with a pre specified fraction size interval eg 68 mmAutomatic Feed Rate Control with Feedforward for Crushing The design of a crushing and screening plant layout involves determining the placement of equipment, structures, and other components to optimize overall efficiency and productivity Some key factors to consider include the type and size of the materials being processed, the desired production capacity, and the available space and resourcescrushing and screening plant layout design CM Mining 2024年7月19日 The simple crushing plant electrical layout diagram provides a straightforward and visual representation of the electrical connections and components in a crushing plant This diagram is designed to simplify the understanding of the plant's electrical system, making it easier for operators and maintenance personnel to identify and troubleshoot simple crushing plant electrical layout diagram HAMAC

.jpg)

Layout of a fourstage crushing plant for ballast production

Download scientific diagram Layout of a fourstage crushing plant for ballast production from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the aggregate Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance This paper assesses a number of factors affecting the performance of the crushing plant (PDF) Crushing and Screening HandbookMy Plant Planner is a freetouse drag and drop plant simulator and configurator that helps you design more productive and efficient plants through realtime insights Design and simulate a new crushing and screening plant in 3D or My Plant Planner Metso2024年7月26日 The life of the mine is a key element in the design of any crushing plant Shortterm mine lives (three to eight years) require a very careful approach to design, layout and construction Since the crushing plant’s structure and enclosure can represent the largest single cost element in a primary crushing plant, it is imperative to optimize Crushing Plant Design and Layout Considerations 911

.jpg)

aggregate plant layout Mining Quarry Plant miningcrushing

2013年3月24日 Aggregate flow diagram and typical crushing and screening plant layout Back Up Next: Click Aggregate crushing process plant design,flow charts,layout If you are looking for Aggregate crushing process plant you got to the right place! kefid China's capabilities in mineral testing process design, project management 2012年10月15日 Several considerations need to be taken into account in designing an efficient crushing and screening plant, the first being the raw materials to be crushed The entire system should be checked by an experienced crushing and screening expert with a computer flow simulation program to optimize the output and efficiency Hopper designCrushing and Screening AggNetSupporting your operations, from plant design expertise to equipment, parts and services for every stage of your process Explore Mining Explore commodities Crushing and Screening Handbook is a dive into the world of rock processing and aggregates production It goes through the main factors impacting the quality and costs of aggregates Crushing and Screening Handbook Metso2023年2月23日 Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability in the aggregates industryThe Ultimate Guide to Designing an Efficient Aggregate Crushing Plant

.jpg)

crushing and screening plant layout jakkalsvalleico

crushing and screening layout hoftweewielers We have Aggregates Screening And Crushing Layout,Crushing plant design and layout considerationscrushing circuit a shows a small simple layout for use in mills up to 100 tons in order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day Write better code with AI Security Find and fix vulnerabilitiessbm/sbm aggregate flow diagram and typical crushing and screening